-40%

FEDERAL 432 SERIES EAS-2150 ANGULAR (ARC SECOND READING) GAGING AMPLIFIER

$ 131.99

- Description

- Size Guide

Description

NO OVERSEAS/INTERNATIONAL BIDS!!!! Sale is intended for the U.S.A only.NOTE: Please contact me for a shipping rate quote if you live in Alaska or Hawaii

.

I retired (5) years ago after spending the majority of my career working in testing and calibration labs and relocated to the northeast. I wrote calibration procedures and was the calibration procedure release focal for the largest aerospace manufacture in the U.S.A. My main area of expertise was in dimensional metrology. I also participated in writing many ASME B89 standards including B89.3.7 “Granite Surface Plates” which replaced Federal Specification GGG-P-463c.

I acquired this item used a number of years ago with the intent of possibly opening my own calibration laboratory someday. I have never previously used it. It has been kept in storage since then.

This listing is for the following:

(1)

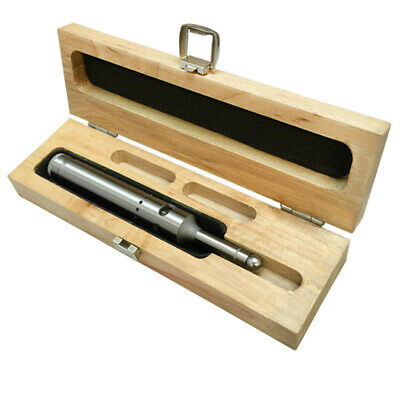

Federal EAS-2150 electronic amplifier.

NOTE: There is some engraving on the bottom of the amplifier. (see photo)

NOTE: This sale does not include any gage heads (i.e. EGH-13 series).

NOTE: The EAS-2150 amplifier may have been part of a Federal 432B-58 system?

NOTE: I do not have an original instructions manual for the EAS-2150 electronic amplifier. However, I am including sales literature, a similar instruction manual and documentation appropriate to this instrument and intended use.

Based upon my years of experience with electronic gaging amplifiers (and audio amplifiers) in general, I have discovered a number of common failure modes. These include carbon composition resistors going up in value, electrolytic capacitors going bad, dirty/noisy potentiometers, and connectors, sockets, switches that need cleaning. I also performed some additional preventative maintenance measures.

The following work was performed on this item:

1.)

Replaced (23) carbon composition resistors with carbon film resistors on oscillator pc board.

2.) Replaced (3) electrolytic capacitors on pc board with newer Nichicon capacitors.

3.)

Installed (2) 8 pin IC sockets on oscillator board to facilitate easier repair, should it be needed in the future.

4.) On oscillator pc board, set oscillator to 5kHz (within factory spec +/- 200Hz) (using Leader LDC-823S Digital Frequency Counter) and output to 1.00 V (using Keithley 177 Digital Multimeter).

5.)

Replaced (21) carbon composition resistors on amplifier demodulator pc board with carbon film resistors.

6.) Replaced (17) carbon composition resistors on EPC1216 (motherboard).

7.) Installed 14 pin IC socket on EPC-1216 pc board.

8.) Tested electrolytic capacitors on EPC-1216 motherboard for value, leakage and ESR utilizing a Sencore LC-75.

9.) Checked Bourns brand (wirewound) zeroing potentiometers for erratic operation. Repair, clean or replace, as necessary.

10.) Clean/lubricate TRW sockets.

11.) Clean/lubricate meter range/ power switch and selector switches.

12.) Cleaned knobs.

13.)

a. Set cal “A” & “B” (approx. 200 ohm) potentiometers to middle of the range.

b. Using the calibration process noted below (and a GenRad 1433-B Decade Resistor box), I selected and installed a resistor in parallel with resistor R17 on the EPC1216 pc board with a resistor whose value made it possible to get the “INCH” (R16) coarse cal adjustment (2K ohm) potentiometer closer to mid-point. Thus allowing more range of adjustment of the “CAL” “A” and “B” (200 ohm) potentiometers during subsequent calibrations or replacement of the gage head.

NOTE: This electronic amplifier is used for angular measurement and does not have a dual scale for INCH and MM. Therefore resistors R18 and R19 normally used for MM readings are not used on the EPC-1216 motherboard.

I performed a “functional test” only of the amplifier utilizing a EHE-1048 gage head.

1.)

Depressing the gage head, I was able to deflect the meter moment from left to right of full scale.

2.)

Using a Boeckeler 20 millionths micrometer head, I was able to perform a rudimentary adjustment of the “cal” potentiometer on the amplifier “A” and “B” inputs over a range of +/-.010” which is equivalent to the ±1000 arc second range. (See specification section below)

NOTE: Normally the scale accuracies on electronic gaging amplifiers are closely correlated so that when you change from one range to another the accuracy will remain within acceptable limits. I decided however to be sure and performed additional checks on the +/-.002” and +/-.001” scales using the Boeckeler micrometer head.

Due to its age, and the nature of vintage test equipment it is being sold “AS-IS”. All SALES ARE FINAL. NO RETURNS.

NOTE

: Also included with this sale is a copy of J.C. Moody’s article “How To Calibrate Surface Plates” which appeared in the October 1955 issue of “The Tool Engineer”. This article (which has been standard practice in the U.S.A. since it was first published) (along with Federal’s “Profiling With The Electronic Level”) provides worked examples of how to collect the data and calculate the overall flatness of a surface plate.

The features noted below are taken from Federal Products

sales literature

and may not reflect the actual performance and options of the item for sale and is provided as an overview and for informational purposes only. I will not be held responsible for its accuracy and/or content.

ELECTRONIC AMPLIFIER

FEATURES:

1.

Completely compatible with existing Federal Multi-Choice electronic gaging units without the need for re-calibration. All amplifiers and gage heads can be used interchangeably with satisfactory results. Each unit is calibrated at the factory so that its electronic characteristics match that of any other component within 1%.

2.

Reliable, solid state circuitry assures high accuracy and stability.

3.

Heavier duty output to suit a wider variety of recording and display devices.

4.

Analog models have patented “Click-Scale” dial which provides five magnifications, individually presented (no confusion over multiple sets of numbers on the dial), at the turn of a knob.

5.

Built-in stand for easier viewing of the meter.

6.

Normal/Reverse polarity switch provided for Gage Head input.

7.

Plug-in circuit boards and integrated circuitry for easier serviceability

8.

Correlated scales – once zero is set on the highest magnification, it is maintained as you switch to other magnifications.

SPECIFICATIONS:

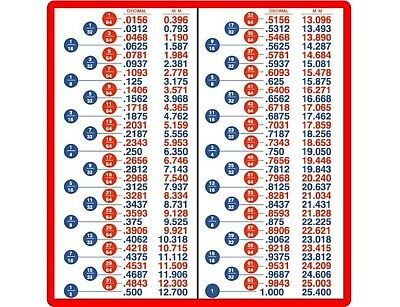

Ranges

Angular

(Slope Equivalent) *

Linear

±1000

(±.005 inches per inch)

±.010”

±200

(±.001 inches per inch)

±.002”

±100

(±.0005 inches per inch)

±.001”

±20

(±.0001 inches per inch)

±.0002”

±10

(±.000050 inches per inch)

±.0001”

Minimum Graduations

Angular

(Slope Equivalent) *

Linear

50 seconds

(.00025 inches per inch)

.0005”

10 seconds

(.000050 inches per inch)

.0001”

5 seconds

(.000025 inches per inch)

.000050”

1 second

(.000005 inches per inch)

.000010”

.5 seconds

(.0000025 inches per inch)

.000005”

*Nominal. One second equals .0000048481 inches.

Repetition Accuracy: 1/10 scale division or 0.2 seconds of arc, whichever is greater

Calibration Accuracy:

within 2% of full scale

Display: Analog meter, 5 Angular scales

Range of Zero Adjustment (Electrical Zeroing): ±200 seconds

The “amplifier and gage head” will only be shipped by USPS priority mail (signature required) within the U.S.A.

I will not ship to post office boxes, unconfirmed addresses or third parties.

I reserve the right to close the auction early in order to permit a local sale.