-40%

Digital Ultrasonic Steel Structure Crack Weld Fault Detector MUT520B

$ 1239.74

- Description

- Size Guide

Description

templateMUT520B Digital Ultrasonic Steel Structure Crack Weld Fault Detector

Product Overview

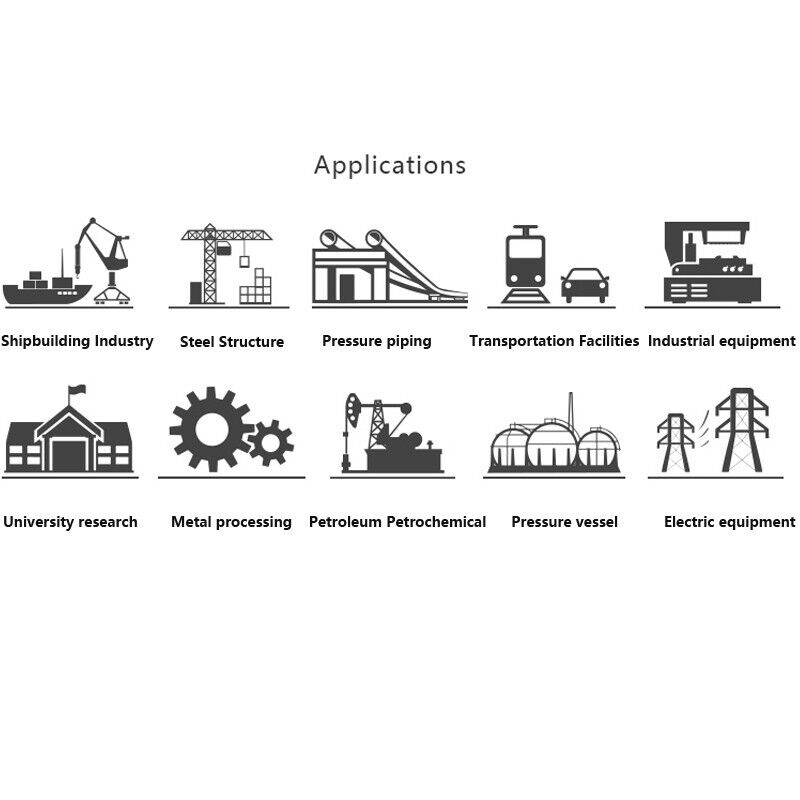

MUT520B Digital Ultrasonic Flaw Detector according to Ultrasonic Propagation Principle - Accurate, Sensitive Workpiece Internal Variety Flaws (Crack, Inclusion, Porosity, Etc) Detection, Positioning, Assessment And Diagnosis. Not Only Can Used In Laboratory, Also In Engineering On-site. 0-6000mm Range Be Satisfied Manufacturing, Iron And Steel Metallurgy Industry, Metal Processing Industry, Chemical Industry And Other Convention Of Defect Detection Needs, Low-Power Design Equipped Large Capacity And High Performance Lithium-ion Battery Module - Long Standby Months Or Above; Quality And Cheap, Practical Economic - Ultrasonic Testing Instrument is Preferred.

Function Use

Technical Parameters

Detection Range:(0~6000) Size (Steel, Longitudinal Wave)

Sound Speed Range:(1000~1500)m/s

Dynamic Range: ≥ 36dB

Vertical Linear Error: ≤ 3.0%

Horizontal Linear Error: ≤ 0.2%

Resolution Power: >40dB (5P14)

Sensitivity Allowance: >60dB (Deep 200mmФ2 Flat Bottom Hole)

With Numbers Inhibition:(0~80)%, Not Loudspeaker's Linear Gain

Electrical Noise Level: ≤ 10%

Probe Type: Straight Probe, Angled Probe, Probes, Transparent Probe

Gate Door: in the Door, Lose Wave Door; Single Gate Readings, Double Gate Readings

Alarm: Buzzer Alarm, LED Light Alarm

Power supply: DC (DC) 9V

Standby Time: >10 Hours

Appearance Size: 263 × 170 × 61(mm)

Environment Temperature :(-10~50)

Symmetrical Humidity:(20~95)%RH

Amplitude: 300V, 500V, 700V Grade Choice, Applicable Probe Wide Range

Pulse Width: In (0.1 ~ 0.512) Μs Range Continuously Adjusts Different Frequency of Probe

Probe Attenuation: 100Ω, 200Ω, 400Ω Selectable, Satisfying Sensitivity And Resolution Of Different Work Requirements

Hardware Real-Time Sampling: High-Resolution 10 AD Adapter, Sampling Rate 160MHz, Waveform Height Fidelity

Detection Mode: Positive Half-Wave, Negative Half-Wave, Full-Wave, RF Detector

Filter Band:(0.5~10)MHz - According to Probe Frequency Fully Automatic Matching, Unnecessary Manual Set

Gate Readings: Single Gate And Double Gate Readings Mode Selectable; Inside the Gate Peak Lectures

Total Amount of Gain of: 110 DB with a 0.1dB, 1dB, 2dB, 6dB Step Value)

Plug-in Socket :BNC/LEMO Selectable

Note: whether above Indicators Is in Probe Frequency for 2.5MHz, Detection Mode for Full-Wave of the Situation below the Measured

Function Features

Gate Alarm

Door, Door Wide, Door High at Will Adjustable; B Gate - Choice Set in the Wave Alarm Or Lose Wave Alarm; Inside the Gate Buzzer And LED Light (Noisy Sound Environment in LED Light Alarm Highly Effective) Alarm And Close

Data storage

Instrument Built-in Mass Storage, Data And File Will Not Be Due To The Instrument And Power Loss, Storage Content Including Channel Parameters, Waveform Image And Video File. Support 50 Group Error Detection Parameters Channel, Pre-Tuned Good All Kinds Probe And Instrument Combination Parameters, Free To The Industry Testing Standard; Can 1000 Error Echo Signal And Parameters, Realize Storage, Readout And Via USB Interface Transmission

Real Time Clock

Real-Time Detection Date, Time Tracking Records, And Records Storage

Communication Port

USB 2.0 High-Speed Communication Transmission Port, Also Can Only Use Software via USB for Data Upload And Download

Battery Module

High Capacity Lithium Battery Module Convenient for Disassembly, Can Separate Charging, Also-Online Charging, Continuous Working Hours Reaches 10 Hours Or Above

Error Detection Function

Inspection Standard: Built-in the Industry Common Fault Detection Standard, Straight Connector Call, Convenient, Fast

Weld Icon: -Set Weld Shape Parameters, Flaw Detection in Visual Display Weld Figure And Defects in Weld Location

Automatic Calibration: Probe Bias And Probe Angle (K Value) Automatic Calibration Function; Sound Speed Automatic Measuring Function

Peak Memory: Real-Time Retrieval Defects Highest Wave, Records Defects Maximum

Flaws Positioning: Real-Time Display Fault Level, Depth (Vertical), Acoustic Location Distance

Defects Quantitative: Defect Equivalent DB Value Real-Time Display

Qualitative Defect: Through the Envelope of Echo Waveform, Convenient Artificial Experience

Curved Surface Fixed: Used in Curved Surface Workpiece Inspection, Real-Time Display Defects Perimeter Location

Digital Analog Dual Purpose: Don't Do AVG Curve, Uses Bottom Wave Gain Method DB Value, Realize Digital Analog Dual Purpose, Convenient for Use

Φ Value Calculation: Straight Probe Forgings Error Find Defects Peak Echo after Automatic Calculation, Display Defect Equivalent Size

DAC/AVG: Curve Automatic Generation, Sampling Point Is Not Limited, And Can Make Compensation And Changes. Curve with Gain Automatic Floating, with Sound Cheng Automatic Expanding, with Delay Automatic China Mobile. Can Display at Will Aperture AVG Curve

Gain: Total Gain Amount of 110dB, Set 0.1dB, 1dB, 2dB, 6dB Step Value, Unique Fully Automatic Gain Control And Scan Gain Function, So That Testing Is Fast And Accurate

AWS D1.1: America Welding Society Standard, for All Kinds of AWS Welding Detection Application Provide A Dynamic Reflector Defects Grading". -Avoid Handmade Calculation, Improve Detection Efficient

Crack Sounding: Utility Endpoint Diffraction Wave Automatic Measurement, Calculation Crack Depth

Indoor Widening: Amplifier Echo Details, Convenient for Echo Analysis

Continuous Records: Real-Time Records, Storage, Waveform Playback

Waveform Freeze: Freeze Screen Displayed on the Waveform, Convenient for Defect Analysis

Echo Coding: Different Color Display 1~6 - Returning Display Area And Distinguish A Wave, Secondary Wave, Convenient For Judging Defects Location

General B Scanning: Real-Time Scanning, Cross Section Shows Created Detection Results More Intuitive

Operating principles

Ultrasonic Testing Is Nondestructive Testing Of Main Method One. It Is Utility Material Itself Or Internal Defects Of Acoustic Properties Of Ultrasonic Propagation Of Loudspeaker, A Nondestructive Detection Material Internal And Surface Defects Such As Crack, Bubble, Slag And Other) The Size, Shape And Distribution Situations And Testing Material Properties. Ultrasonic Testing Has High Sensitivity, Transparent Strong, Test Speed And Low Cost, Equipment Simple, Light And Harmless To The Human Body And A Series Of Advantages.

Working conditions

Environment Temperature: (-10~50)

Symmetrical Humidity: (20~95)%RH

Instrument Features

Gate Alarm

Door, Door Wide, Door High at Will Adjustable; B Gate - Choice Set in the Wave Alarm Or Lose Wave Alarm; Inside the Gate Buzzer And LED Light (Noisy Sound Environment in LED Light Alarm Highly Effective) Alarm And Close

Data storage

Instrument Built-in Mass Storage, Data And File Will Not Be Due To The Instrument And Power Loss, Storage Content Including Channel Parameters, Waveform Image And Video File. Support 50 Group Error Detection Parameters Channel, Pre-Tuned Good All Kinds Probe And Instrument Combination Parameters, Free To The Industry Testing Standard; Can 1000 Error Echo Signal And Parameters, Realize Storage, Readout And Via USB Interface Transmission

Real Time Clock

Real-Time Detection Date, Time Tracking Records, And Records Storage

Communication Port

USB 2.0 High-Speed Communication Transmission Port, Also Can Only Use Software via USB for Data Upload And Download

Battery Module

High Capacity Lithium Battery Module Convenient for Disassembly, Can Separate Charging, Also-Online Charging, Continuous Working Hours Reaches 10 Hours Or Above

Error Detection Function

Inspection Standard: Built-in the Industry Common Fault Detection Standard, Straight Connector Call, Convenient, Fast

Weld Icon: -Set Weld Shape Parameters, Flaw Detection in Visual Display Weld Figure And Defects in Weld Location

Automatic Calibration: Probe Bias And Probe Angle (K Value) Automatic Calibration Function; Sound Speed Automatic Measuring Function

Peak Memory: Real-Time Retrieval Defects Highest Wave, Records Defects Maximum

Flaws Positioning: Real-Time Display Fault Level, Depth (Vertical), Acoustic Location Distance

Defects Quantitative: Defect Equivalent DB Value Real-Time Display

Qualitative Defect: Through the Envelope of Echo Waveform, Convenient Artificial Experience

Curved Surface Fixed: Used in Curved Surface Workpiece Inspection, Real-Time Display Defects Perimeter Location

Digital Analog Dual Purpose: Don't Do AVG Curve, Uses Bottom Wave Gain Method DB Value, Realize Digital Analog Dual Purpose, Convenient for Use

Φ Value Calculation: Straight Probe Forgings Error Find Defects Peak Echo after Automatic Calculation, Display Defect Equivalent Size

DAC/AVG: Curve Automatic Generation, Sampling Point Is Not Limited, And Can Make Compensation And Changes. Curve with Gain Automatic Floating, with Sound Cheng Automatic Expanding, with Delay Automatic China Mobile. Can Display at Will Aperture AVG Curve

Gain: Total Gain Amount of 110dB, Set 0.1dB, 1dB, 2dB, 6dB Step Value, Unique Fully Automatic Gain Control And Scan Gain Function, So That Testing Is Fast And Accurate

AWS D1.1: America Welding Society Standard, for All Kinds of AWS Welding Detection Application Provide A Dynamic Reflector Defects Grading". -Avoid Handmade Calculation, Improve Detection Efficient

Crack Sounding: Utility Endpoint Diffraction Wave Automatic Measurement, Calculation Crack Depth

Indoor Widening: Amplifier Echo Details, Convenient for Echo Analysis

Continuous Records: Real-Time Records, Storage, Waveform Playback

Waveform Freeze: Freeze Screen Displayed on the Waveform, Convenient for Defect Analysis

Echo Coding: Different Color Display 1~6 - Returning Display Area And Distinguish A Wave, Secondary Wave, Convenient For Judging Defects Location

General B Scanning: Real-Time Scanning, Cross Section Shows Created Detection Results More Intuitive

Operational Methods And Precautions

Button Operation, Shouldn't Be Too Hard, Shouldn't Use Stained With Too Much Oil And Mud Fender Hand Operation Instrument Keypad, In Order To Ensure Speaker Keypad Of Lifespan

Error Detector After Use, Response Instrument Appearance Cleaning

Instrument Must Be Stored in Dry Cleaning Places

Instrument Should Avoid Oil Or Water And Other Liquid In Instrument Internal, Frequently Cleaning Instrument Surface

Probe Wire, Communication Cable And Avoid Twisted Weight; In Plug Cable Connectors, Must Grab Plug from Root, Don't Grab Cable Pull, Block Or Drag

Instrument Maintenance And Maintenance

Carefully Check Any Information Whether Completed, The Instrument And Accessories And Packing List Is Consistent, Roogo Inappropriate, Please Contact You And I Company. Carefully Carefully Read Meter Information, To Ensure You Gain Due Game Of Thrones And Services

Roogo in Instrument Use Process in Sound Accident, Cause Instrument Abnormal Situation, Not Working, Turn-off Instrument And Battery Of Connection(Will Battery Switch Commodity Shelf Off"), And Wait 1 Minute After Served As New Boot

I Company This Instrument Provide One Year Warranty, Lifelong Maintenance. Instrument Maintenance Matters You And I Company Or Instrument Dealer Contact, Not Recommended Self-Maintenance

1.Your valid phone number is very necessary for the shipping, otherwise we can't guarantee that the package would safely arrives.

2. Any Customs tax applied to this package should be covered by buyers.

3.As has been stated on the eBay item description, Import duties, taxes and charges are not included in the item price and shipping charges. These charges be at the buyer responsibility. meanwhile the customs tax depend on the buyer local customs office.

What in Package:

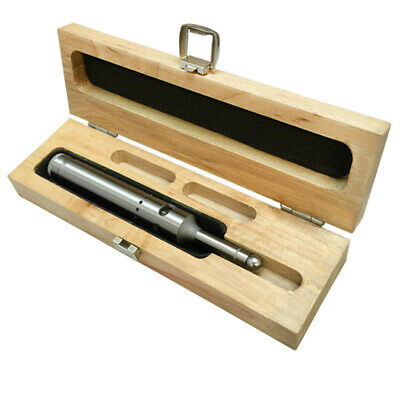

1 x MUT520B Digital Ultrasonic Fault Detector

Contact Us:

1. We have always been trying to provide the best service and reliable products for every customer, however, accident may happen sometimes, please contact us to resolve any issue before leaving a negative feedback.

2. Please contact us by "Ask a question".

Payment

1. Payment methods accepted :

Paypal

only

.

2. Payment must be received within 7 business days of auction closing.

Shipping

1. We ship your orders within 1-2 business days after the payment received.

2. Item shipped via Singapore Post or HongKong Post , It takes about 7-14 business days (USA,CA,AU,UK).others country 10-20 business days(Brzil,India,RU),Exact delivery time depends on postal process.

3. If you do not receive your item(s) by 30 business days,Please feel free to contact us via ebay mail system , we will try our very best to resolve any problems with you

Return Policy

1. Return is accepted within 14 days after the buyer's receiving the item.

2. If this item is defective upon receipt, customer has up to 14 days from date of receipt for exchange of a new one.

3. Unused/unopened merchandise will be fully credited.

Other Policies

We are not responsible for any custom duty or import tax.

If you need we write low price on shipping bill, pls leave message when you make payment .

All emails will be answered within 24 hours. If you do not receive our reply, please kindly re-sent your email and we will reply to you as soon as possible, Suggest send eBay message to us, That is easy to find .