-40%

Corner Center Zero Edge Finder CNC EF3x2 for non-metalic or irregular shapes USA

$ 11.61

- Description

- Size Guide

Description

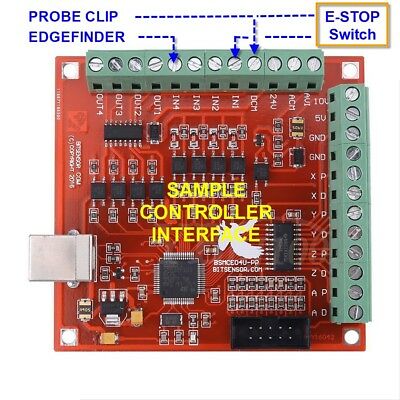

The model CNC-EF3x2 developed by Vancura Innovations is designed to aid in the finding of the edge of non-conducting materials like plastics and wood. Rugged all aluminum construction with convenient screw for attaching a ground wire. Compatible with MACH3 CNC software.

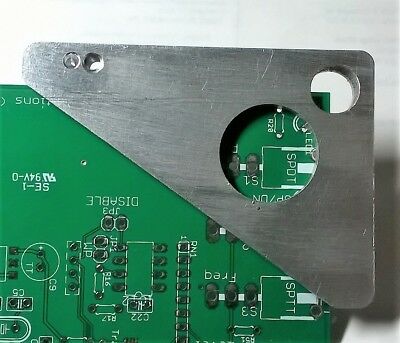

The hole over the corner greatly simplifies finding the actual corner of the stock material. A center-of-hole finding routine is simpler and more repeatable than any other method, and having it directly over the material corner is

most

convenient. This tool is particularly useful for creating a repeatable reference point for your work piece, especially if the tool breaks or needs changing.

The edge finder's open corner design accepts small deformities in the work stock and minimizes buildup of dirt and chips that limit accuracy and repeatable measurements.

The smaller hole over the corner is suitable for use with 1/4" and 1/8" probes, and is centered directly over the corner. The larger hole is 0.75 in diameter and is suitable for larger probes or tools, and is 0.50" x 0.50" from the material corner. The large hole also makes handling the edge finder eas

y

. This edge finder is large enough to easily handle and place for measurement, yet small enough to avoid most work holding clamp arrangements. It is 1/4" thi

ck

to allow use in limited space and offers a 1/8" pocket for a reliable alignment with your material. The top surface makes a great way to find the top of the material without risking damage to the work surface.

To use the edge finder, connect a ground wire to the edge finder and clip the sense wire to your probe (or router bit) and implement a center finding routine. The routine should: first: find x-, then x+, calculate center of x as zero, go to x=0; second: find y-, then y+, calculate center of y as zero, go to y=0; third: repeat find center of x- & x+; optional: repeat find center of y- & y+. Always seek either x- or y- first, because if you forget to connect the sense wire (or the wire breaks), it will only push the edge finder off the material instead of breaking something before you can stop the process. Note: if the tool happens to be grounded through the spindle, connect the sense wire to the edge finder.

Three way sensing of the edge or corner:

1) Center finding using the smaller hole. Center is directly over the corner.

2) Center finding of the larger hole. Center of 0.75" hole is 0.50" x 0.50" from material corner

3) Edge finding using outside surface edge is 0.30 from outside surface.

The top surface can also be used to find the top of the material with an offset of 1/8".

Note: User is responsible for verifying the accuracy of the edges and hole centers. The machining will vary slightly from unit to unit.

Specifications

:

Size:

2.

7" x 1.95" x 1/4" thick.

Small hole: 3/8" dia. Offset from corner 0.000" x 0.000". Depth of hole for probe 0.12".

Large hole 0.75" dia. Offset from corner 0.500" x 0.500". Depth of hole for probe 0.12".

Pocket is 1/8" deep.

Material

:

6061 Aluminum. Screw 6/32x1/4 " steel.

What You get in the package:

One (1) edge finder with grounding screw.

Installation instruction sheet.

(Contact seller for additional information on installation and sample Mach3 edge finding routines.)